Top Tips For Avoiding Pitfalls With Solder And Flux

Today all of us depend upon and expect high reliability, it’s no longer just represented in very sophisticated systems. Our high expectation of reliability in our devices now forms part of our everyday lives, and solder, and indeed flux, are a critical factor, essentially binding our world together. Whether products are portable devices within the consumer electronics sector or systems used in high-reliability military hardware, advances in soldering technology have assisted with these developments.

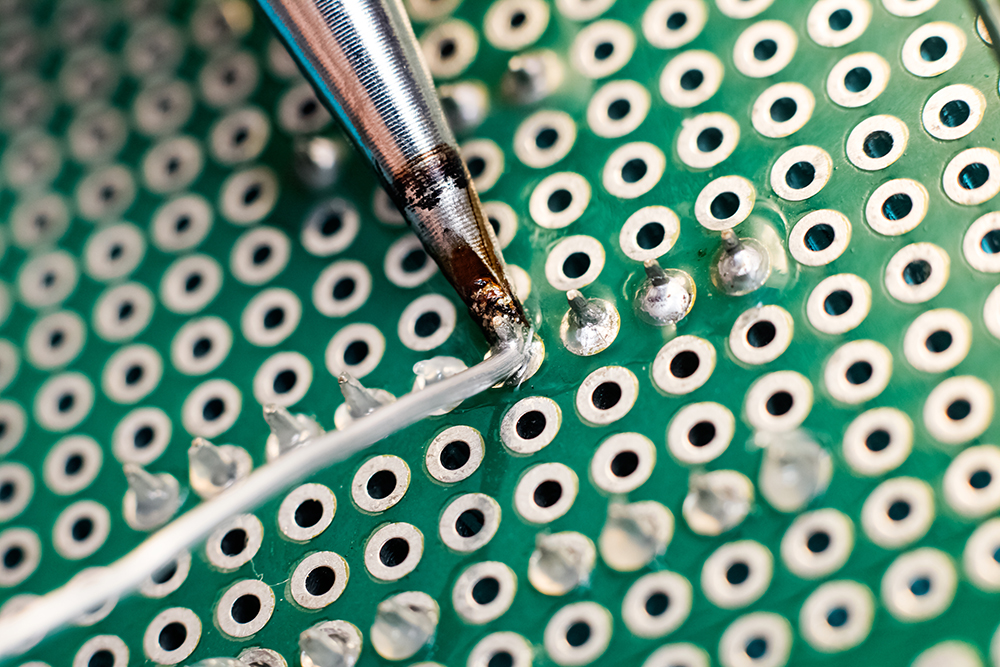

In this edition of Hakko Tech Tips, we will explore some questions we customarily receive regarding some of the potential pain-points with solder and flux and how best to avoid these pitfalls, to help you achieve your seamless soldering goals. Hakko has gained a solid reputation worldwide for its wide range of soldering and de-soldering solutions that make quick and easy work of different applications as well as reducing costs, improving performance and boosting work-in-progress. So, let’s take a closer look at this month’s top tips:

1) Should you turn on your soldering station way before you intend to use it, and if not, what are the consequences of doing this?

The simple answer to this, is no. The warm up time for all Hakko Soldering and Rework equipment from ambient to set point temperature is extremely short, i.e. seconds. As a result there is no reason to power up your soldering station far in advance before use is required. In fact, this would be detrimental to the solder tip/heater life and consume excessive amounts of power. If the unit is switched on and idle for prolonged periods, most Hakko equipment has idle and sleep facilities built into the standard software. These will intervene and either reduce the run temperature or completely power the station down. Please note that these are programmable facilities and can be switched on and off as required.

2) What are your top tips to resolve a problem such as the solder not flowing as you would like it to?

There can be many reasons why solder will not flow during use. The first port of call should always be the set point of the solder station and the solder tip selected. Most applications will require a set temperature of between 340 to 380 °C. However, where soldering of large pads, components or heavy ground planes is required, it may be necessary to increase the temperature as high as 420 °C.

Most solders (Leaded or Lead Free) will utilise an alloy which melts at between 179 and 227 °C. As the Lead content reduced the surface tension of Tin/Lead alloys, the molten alloy was much more likely to flow during operation. Conversely, Lead Free alloys do not contain Lead so have a higher surface tension that will not allow flow in the same manner. More active flux within solder wires could help, or even the application of an external flux source. If the aforementioned avenues have all been explored, then there could possibly be a problem with the solderability of the component, PCB or both. At this stage, assistance from your component or material supplier is probably required to test the solderability of the parts to be soldered.

3) What are the possible reasons that are preventing my solder from sticking correctly?

A soldered joint is unique in that, when complete, it should form two intermetallic layers at the component/solder and PCB/solder interfaces, i.e. the solder enters the grain structure of the mother materials, forming a new alloy. This is unlike an adhesive bond, which is a surface joint containing the three different base materials. If there is oxidation on either or both of the parts to be soldered, this will act as a barrier for the flux/solder, resulting in a weak joint that can be peeled or broken away. Physically or chemically cleaning the component/PCB or use of a more aggressive flux may help cut through the oxidation and aid wetting. Again, as in Paragraph 2 above, if the problems persist, components and/or PCB’s should be tested for good solderability

4) What will happen if I overheat the flux?

Most solder wires contain a small amount of flux, typically around 2% to 3%. If excessive heat is applied during the production of a soldered joint, the worst case scenario would be damage to the component and PCB. A major contributory factor to this could be the exhaustion of the flux. When this happens, oxidation increases and flow of the molten solder is restricted. Potentially any flux residues left behind could then be “caramelized” leading to poor visual appearance and, if cleaning is required, a hard residue which is difficult to remove.

5) Is it possible to use too much flux when soldering?

To be honest, it depends. In theory, no! If a PCB assembly is machine soldered, it is likely to have had the whole underside of the PCB coated in flux. However, in some industries all flux residues must be removed from the PCB prior to conformal coating, encapsulation, etc. So it needs to be remembered that the less flux that is applied in the first place is less to be removed at a later stage. Note that there are many different types of flux available from a wide range of manufacturers. The classification of flux used will determine if the residues can be removed, how corrosive they are and how quickly they should be removed. We welcome feedback from our customers and potential new customers, so please do talk to one of our team if you have any questions. Look out for next month’s Hakko Tech Tips where we will be providing more advice on how to get the best performance from your Hakko equipment.