Search by operation

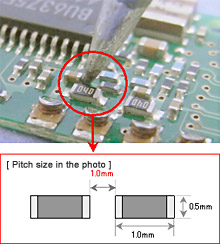

Soldering at the narrow pitches

The following tip shapes are recommended. Please select the best shape by following each feature.

* Click icon and jump to each tip shape details.

| Feature | Remarks | |

|---|---|---|

| Shape I | This shape has a thin conical end and is an ultrafine tip. It is best suited for soldering at narrow pitches. | – |

| Shape K | This shape has a shape like a knife. It is also available for correcting bridging and drag soldering. | These shapes are recommended when unmolded solder caused by insufficient heat capacity with Shape I |

| Shape S | This shape is changed from Shape B, C, D and I by the special shape which prevents tip end to touch the nearby ICs. |

Use Shape I

This shape has a thin conical end and is an ultrafine tip. It is used for soldering a tiny chip at narrow pitches.

| It is easy to work with Shape I at the narrow pitches in which the tip end of Shape B touches the nearby ICs. |

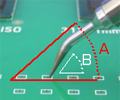

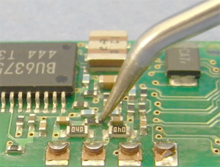

Use Shape J

This shape differs from Shape B and I by bending the tip end and is capable of soldering by applying the tip in 2 ways: face and point. It offers other recommended usages.

Enlarge the tip end, | You can hold the grip with the natural angle (Refer to A) while soldering with Shape J, which has the same high-angle of tip end (Refer to B) as Shape I.

|

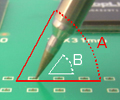

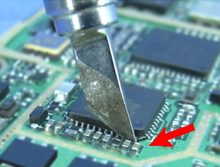

Use Shape K

This type has a shape like a knife and is capable of soldering by applying the tip in 3 ways: line, face and point. It is used for soldering at narrow pitches, correction of bridging and drag soldering.

| Stand the blade on edge and put the tip end on the leads of the IC chip.

|

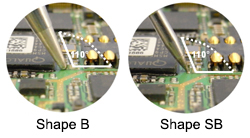

Use Narrow-pitch Soldering Type : Shape S

This shape is derived from Shape B, C, D and I. It is used for soldering tiny chips at the narrow pitches.

| The special shape of fine tip end prevents its tip end from touching nearby chips.

|