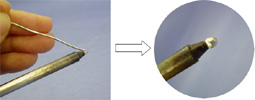

If solder is not wet on the tip surface, the tip is oxidized.

*Example of an oxidized tip that has blackened due to oxidization

Case 1. If the tip oxidizes.

Point 1: | Use cleaning wire (HAKKO 599B) or fine sandpaper to remove only the surface oxide. Apply new solder to the tip at 250ºC. | ||||||||||

Point 2: |

Remove oxide and recover the tip surface with chemical paste ( HAKKO FS-100 ) * After using the FS-100 paste, clean the tip according to the following procedure. * Do not use the chemical paste for purposes other than restoring of the soldering tip. How to remove oxide with HAKKO FS-100:

| ||||||||||

| Point 3: | The removal process will be more effective if tip polisher (HAKKO FT-700) is also used. | ||||||||||

| Point 4: |

If solder is not wet to tip surface after removing the oxidation, replace the tip with a new one. See individual product webpage for part numbers of soldering tips. Lineup of Soldering iron | ||||||||||

Case 2. How to prevent tip oxidization.

| Point 5: |

Always keep the end of the tip coated with solder so as not to expose it to the air. After finishing work:

| ||||||||

| Point 6: |

Use HAKKO 599B (cleaning wire).

| ||||||||

| Point 7: | Turn the power off when not using the iron. | ||||||||

| Point 8: | Use soldering iron at lower set temperature.(Do not raise the temperature unnecessarily.) | ||||||||