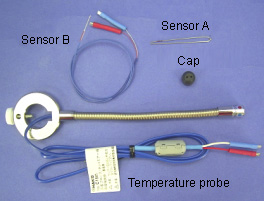

The Temperature Probe for Hot Air Rework System (No. C1541) is equipped with 2 types of sensors. Before measuring temperatures as follows, connect the sensor to the thermometer ( HAKKO FG-100B, HAKKO FG-100(Discontinued) and HAKKO FG-101).

| Sensor A: | When measuring the temperature of hot air blown from the nozzle: Correcting thermal control can be made by confirming the temperature of the hot air that is actually blown. How to use Sensor A |

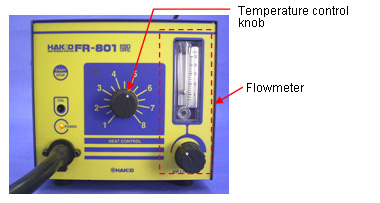

| Applicable products: | SMD rework HAKKO FR-801, HAKKO FR-802, HAKKO FR-803B, HAKKO 850B, HAKKO 852, HAKKO FR-830, HAKKO FM-2029 |

| Sensor B: | When measuring the temperature of applicable parts (workpieces): Rework can be performed without causing damage to the parts being reworked (QFP, etc.) How to use Sensor B |

Let’s use Sensor B to determine the Hot Air setting conditions required for rework! * When performing similar work using multiple Hot Air Rework Systems, see the following pages.

1) Check the specifications for the workpiece.

* The procedures will be explained using the HAKKO FR-801 as a sample as follows:

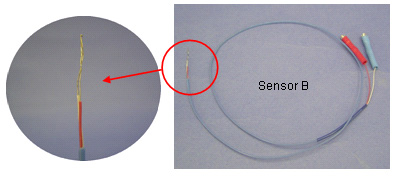

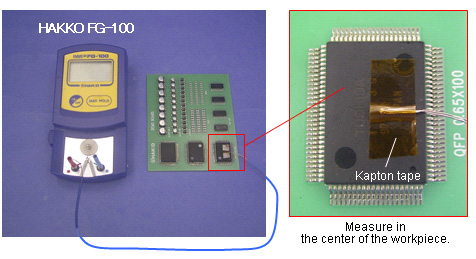

2) Attach the end of Sensor B to the section of the workpiece to be reworked using thermoset adhesive or a Kapton tape. Attach the other side of Sensor B to the thermometer.

* The procedures will be explained using the HAKKO FR-801 as a sample as follows:

Thermometer lineup: HAKKO FG-100B、HAKKO FG-100(Discontinued)、HAKKO FG-101、HAKKO FG-102

* Photo of the FG-100 discontined.

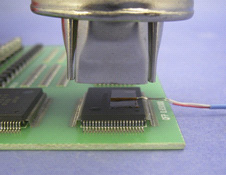

3) Attach the nozzle suitable for the workpiece to the HAKKO FR-801 and switch it on.

Temperature of hot air varies by the distance between the nozzle and the workpiece, ambient environment, room temperature, etc. Operation should be performed under the actual work environment such as with air conditioner, etc.

4) Measure the temperature of the workpiece.

5) Adjust the temperature of Hot Air Rework System so that the temperature of the workpiece becomes the specified heat-withstand temperature.

* For digital Hot Air models such as HAKKO FR-802, HAKKO FR-803B, etc., adjust the temperature based on the offset values.

Be careful that hot air is applied to only the end section. Failure to do so may not allow correct temperature to be measured.