Search by operation

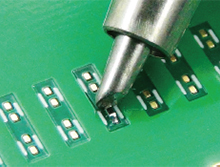

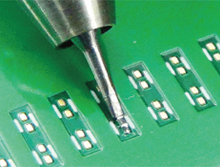

Soldering tiny chip parts such as 0603

The following shapes are recommended. It introduces how to select the size of tip.

* Click icon and jump to each tip shape details.

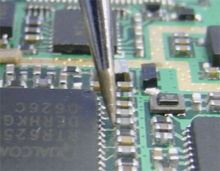

The recommended tip size is the same size of A or “A-0.1mm”.

(see the right picture)

Tip with larger size than “A” can also be used if it does not contact with adjacent components.

As long as the size fits, “I”, “J”, “S” or other shapes can be used.

However, even if the size and shape fit, there may be problems such as cracking on multiple ceramic capacitors due to the thermal stress of soldering and insufficient heating on multilayer PWB.

Such problems can be improved by pre-heating with N2 gas soldering iron just before soldering.

N2 system required equipments or compatible soldering stations/irons

HAKKO FM-2032 and FX-1002 with their tips are designed for micro soldering under micro-scope. FM-2032 has an option for the use of N2 gas.

|  |

| Micro soldering iron HAKKO FM-2032

| IH Micro soldering iron HAKKO FX-1002

|

Use Shape BC/C

This type has a shape like a cone or column cut at a slant, which allows users to select the cut surface size depending on the workpiece. It is used for drag soldering and pre-tinning of lead wires.

| Put the cut surface to the land. Some IC is specified by manufacturer not to be touched electrode by tip end. |

Use Shape D

This type has a shape like a flat-blade screwdriver and is capable of soldering by applying the tip in 2 ways: line and face. It is available for any works.

| Put the tip end to the land. Some IC is specified by manufacturer not to be touched electrode by tip end. |

Use Shape I

This shape has a thin conical end and is an ultrafine tip. It is used for soldering a tiny chip at narrow pitches.

| Very fine tip end makes it easy to solder a tiny chip. |

Use Shape J

This shape differs from Shape B and I by bending the tip end and is capable of soldering by applying the tip in 2 ways: face and point. It offers other recommended usages.

| Lay down the end pad section and put the tip to the land. Some IC is specified by manufacturer not to be touched electrode by tip end. |

Use Shape K

This type has a shape like a knife and is capable of soldering by applying the tip in 3 ways: line, face and point. It is used for soldering at narrow pitches, correction of bridging and drag soldering.

| Put the tip to the leads while laying down the entire blade. Some IC is specified by manufacturer not to be touched electrode by tip end. |

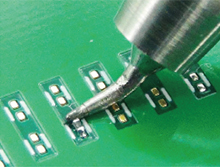

Use Narrow-pitch Soldering Type : Shape S

This shape is derived from Shape B, C, D and I. It is used for soldering tiny chips at the narrow pitches.

| Shape SB : Tip end size R0.2 The special shape of fine tip end makes it easy to solder a tiny chip. |

| Shape S : Tip end size R0.5 |