-

How to use Shape BCM/CM and examples

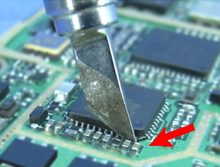

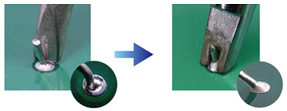

This type differs from Shape BC by the addition of a hollow to its cut face, providing high solder retention capability.

It is used for drag soldering and correction of bridging. Usage HintsDrag soldering

Correcting Bridging

– If amount is small –

This hollow is the secret.

(Shape BCM Sample T12-BCM3)

-

How to use Shape BC/C and examples

This type has a shape like a cone or column cut at a slant, which allows users to select the cut surface size depending on the workpiece.

It is used for drag soldering and pre-tinning of lead wires. Usage HintsDrag soldering

Pre-tinning lead wire

(Shape BC Sample

T12-BC3)

(Shape C Sample

T12-C4)

-

How to use Shape B and examples

All-round type which can be used from any direction and is easy to hold at any position.

Possible to solder any surface from small to large. Usage HintsDrag soldering

Point soldering

Soldering chip parts

-

How to use Shape D and examples

This type has a shape like a flat-blade screwdriver and is capable of soldering by applying the tip in 2 ways: line and face.

The width (size of tip) suitable for the workpiece can be selected, and it can be used for any soldering work. Usage HintsDrag soldering

Soldering chip parts

This shape is capable of any soldering by placing the tip end in 2 ways: line and face.

-

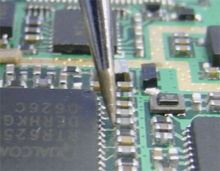

How to use Shape I and examples

This type has a thin conical end and is an ultrafine tip which is best suited for soldering at narrow pitches, etc.

It is the best for soldering micro components such as 0603, etc. and for repairing high-density-mounting P.W.Bs. such as in cellular phones, etc. Usage HintsSoldering at

the narrow pitches

Soldering tiny chip parts

-

How to use Shape J and examples

This type differs from Shape B and I by bending the tip end and is capable of soldering by applying the tip in 2 ways: face and point.

It is used for drag soldering and correction of bridging. Usage HintsDrag soldering

Correcting Bridging

– If amount is small –

Correcting Bridging

– If amount is large –

-

How to use Shape K and examples

This type has a shape like a knife and is capable of soldering by applying the tip in 3 ways: line, face and point. It is used for soldering at narrow pitches, correction of bridging and drag soldering. Usage HintsSoldering at

the narrow pitches

Correcting Bridging

– If amount is small –

Correcting Bridging

– If amount is large –

Drag soldering

-

How to use SMD Type : Shape Quad and examples

This type is capable of heating plural pins or lead wires at once and is used for rework of SMDs.

It is used for removal of QFP. Usage HintsRemoving QFP

This shape is capable of heating IC lead wires on all 4 sides at the same time.

-

How to use SMD Type : Shape Tunnel and examples

This type is capable of heating plural pins or lead wires at once and is used for rework of SMDs.

It is used for removal of SOP. Usage HintsRemoving SOP

This shape is capable of heating IC lead wires on 2 sides at the same time.

-

How to use SMD Type : Shape Spatula and examples

This type is capable of heating plural pins or lead wires at once and is used for rework of SMDs.

Soldering for thermal compression of flexible P.W.B., shield cases, connecter, etc. Usage HintsSoldering for thermal compression of flexible P.W.B., shield cases, connecter, etc.

This shape is capable of heating IC lead wires on one side of a wide IC, connector, etc.

This shape is also convenient for cleaning after removal of BGA.

-

How to use Shape A and examples

This type is like a square pyramid and all-round tip shape such as Shape B.

It is possible to solder any surface from small to large.

-

How to use Shape H and examples

This type differs from Shape J by cutting the tip end.

It is suitable for drag soldering and correction of bridging.

* Not available for correcting bridging by standing the tip end like Shape J. Usage HintsDrag soldering

Correcting Bridging

– If amount is small –

Correcting Bridging

– If amount is large –

-

How to use Shape R and examples

This type has a groove at the tip end.

It is suitable for removing ICs. Usage HintsRemoving ICs

-

How to use Narrow-pitch Soldering Type : Shape S and examples

It is derived from Shape B, C, D and I, which is used for soldering at the narrow pitches.

Try Shape S as well as Shape I or K if the tip end of Standard type touches the nearby ICs. Usage HintsSoldering at the narrow pitches

This type has the tiered design: the nearer to the tip end, the thinner the diameter.

-

How to use Shape Concave and examples

This type has a concave (or V-groove) at the end.

It provides excellent heat supply to solder joint and ensures sufficient solder flow-up. Usage HintsInsufficient flow-up Successful flow-up

- How to use Heavy Duty Type and examples

This type is changed from basic types B, D and I by special processing.

It is changed by thickening the entire tip to increase heat storage and is the best for work needing high heat capacity.

- How to use Long Life Type and examples

This type is changed from basic types B, BC, C, D and K by special processing.

Our special treatment allows a tip to last about double longer than the standard type. It’s the optimum approach for the short life tip by corrosion hole.